Our Infrastructure

Samay consists of several departments that are each responsible for specific elements of the overall Manufacturing process, from design to commissioning. All company departments communicate via the latest available technology, which ensures integration of idea

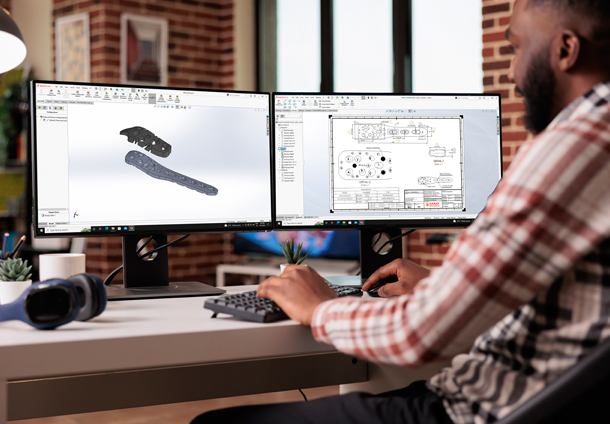

PRODUCT DESIGN (CAD)

All the research & development activities are conducted indigenously by a team of experienced and skilled members. The new products are developed under the guidance of senior surgeons & technical consultants. A true to model accuracy is designed and achieved with highest commitment & dedicated team work of mechanical engineers & technicians.

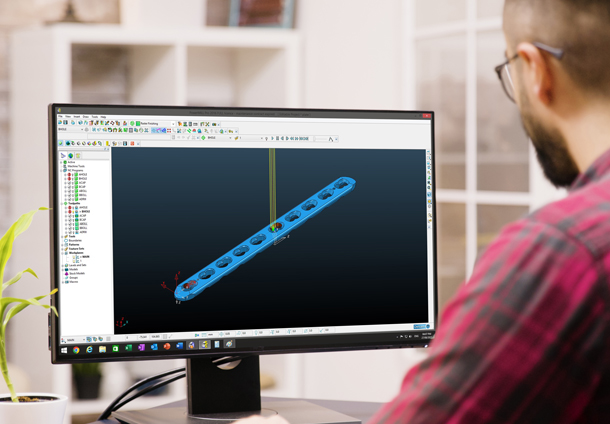

COMPUTER AIDED MANUFACTURING (CAM)

We make use of the latest technology to revolutionize our products and keep them updated. For that matter, we use the CAM programs to bring the most efficient Products for our clients. We ensure the best results with the help of precision machining. And provide the most effective Products to our customer

LINE INSPECTION

The line inspection ensures that the desired quality parameters are maintained at each level of manufacturing process. Each Part is thoroughly checked before transferring to the next level of machining. The system ensures that the non-conformance is verified at every stage and the right product reaches to the next process. Line inspection is carried out by skilled & experienced QC team.

PRODUCTION

Our production processes are designed to offer our clients the maximum flexibility to incorporate their special requirements in keeping with quality control parameters. The entire machining process has been diversified to high-capacity, state-of-the-art Computerized Numerical Control (CNC) machines, enabling us to maintain prompt delivery schedules and meet your requirements on time. Each part is manufactured with high-precision tools by skilled and experienced machine operators and supervisors. Special purpose machines have been designed to handle all critical applications.

RAW MATERIAL

We believe that the best products can be manufactured only from the best raw material. The materials used in the manufacturing of medical devices must possess excellent chemical and physical properties, along with high purity and corrosion resistance. Therefore, we ensure that our raw materials are sourcing from internationally recognized premium-quality suppliers. We source our raw materials from trusted international suppliers known for their premium quality. Once imported, the material is subjected to testing and quality checking to make sure it meets our high standards of quality. The materials are tested by a reputed laboratory for each and every lot and the traceability is maintained throughout the manufacturing process.

CLEAN ROOM

Our clean-rooms are designed according to ISO Class 7 and Class 8 standards to maintain packaging integrity and ensure proper packaging without physical damage or biological contamination

PACKAGING & MARKING

A. The packaging of finally inspected products is carried out in a clean room to ensure the cleanest and safest devices. Every product is individually sealed in pouches and label. Laser marking is used to inscribe information on the implant, ensuring you receive a genuine product.